Description:

Product Introduction

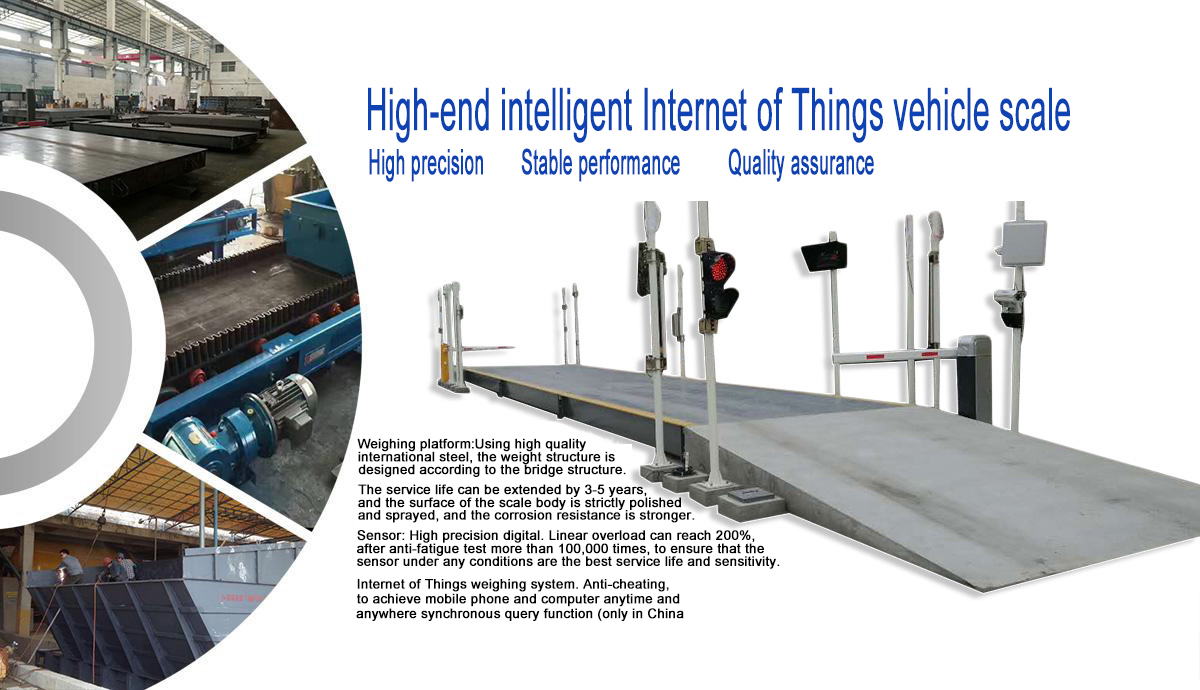

SCS high-end digital car scale (weighbridge): equipped with original high-end imported digital weighing sensors and digital weighing displays, modular weighing platform, waterproof, lightning protection, anti cheating, anti rat bite cable, professional weighing software, matched with Lenovo computer set and Epson printer. High end accessories have improved the quality of the weighing scale, making it easier to debug, safer to use, simpler to maintain, more convenient to communicate, more intelligent, and more anti-interference.

Product advantages

1. High end imported digital weighing sensors adopt digital technology, which can automatically digital compensate for temperature coefficient, nonlinearity, hysteresis, and creep; Digitalization of transmission signals can effectively prevent electromagnetic signal remote control interference and achieve anti cheating effects.

2. The system design can withstand lightning protection of 100000A and 99.9%.

3. Waterproof grade IP69, suitable for outdoor operations in areas with frequent thunderstorms.

4. The weighing platform is made of elastic steel, which has good rigidity; The international standard U-shaped steel bridge beam structure has strong load-bearing capacity for the weighing platform; Rust removal and oxidation treatment, sandblasting and spray painting, durable weighing platform, and exquisite appearance.

5. The design of the weighing platform is modular, standardized, and serialized, and can be composed of multiple specifications. The entire digital weighing system has strong environmental adaptability, superior measurement performance, high accuracy, good long-term stability, and convenient installation, debugging, and maintenance.

Applicable occasions

Widely used in metallurgy, mining, machinery, chemical industry, ports, and highway freight station industries.

SCS digital car scale (weighbridge) parameters

Model SCS Accuracy Level III Maximum Weighing 1-300T Minimum Weighing 40kg-400kg Scale Value 0.1 kg -10kg Overload Factor 150% Interface Method Rs485 Signal Transmission Distance ≤ 1000m Transmission Baud Rate ≤ 19200bps Signal Power Supply DC12V, Not Less than 600mA Product Execution Standard GB/7723-2008 Display 7-bit Digital Tube, 7 Status Indicators Transmission Method RS232/RS485 AC Input AC110~220V 50~60HZ Auxiliary Power Supply DC12V Usage Temperature -20~60 ° C Storage and Transportation Temperature -40~70 Relative Humidity ≤ 85% RH 10 Anti Cheating 99.9% Anti Cheating Lightning Protection Thickness Standard 10-14mm Customizable for other thicknesses) Size standard width: 3-3.5 meters Length: 16-24 meters (customizable) Material A3 steel (Shanghai Baosteel, Shaogang) Density 7.85g/cm3 Overload capacity 150% F.S Extreme overload 200% F.S Digital module effective resolution A/D 100000 code Data refresh rate 50HZ Communication baud rate 9600BPS Accuracy ± 0.02% F.S Suitable temperature -30~70 degrees Celsius Zero point output ± 0.1% F.S Safety overload 150% F.S Protection level IP68 Recommended voltage 9-12VDC Maximum voltage 20VDC Signal transmission distance 1200m Sensor rated load 20,25,30,40 Rated output 20000 25000 30000 40000 codes

To better select the ideal product for users, please carefully read the following content:

1. Scope of use of weighing scale: The correct range of use of weighing scale is about 70%, and the upper limit of weighing scale generally does not exceed 90%. Long term load use affects the service life of sensors. Select the scale that is suitable for your normal range of use. For example, if the general weighing range is around 70t, a 100t weighbridge should be selected.

2. Weighbridge Function Selection: According to different user needs, the selection of high-precision, lightning protection, waterproof, ultimate load and other functions varies. You can choose imported high-end imported sensors (imported supporting equipment) or domestically produced high-end sensors. For example, there are many thunderstorms in spring and summer in Guangdong, and outdoor weighing scales (car scales) need to purchase imported lightning protection sensors. Once they are damaged, the cost of replacing a set of sensors is also quite expensive.

3. Scale selection: ① Customize suitable scales for different users according to their different usage scenarios. For example, in chemical plants, corrosion-resistant weighing platforms are required. Depending on the corrosion level, suitable stainless steel materials and corrosion-resistant painted weighing platforms can be customized to increase their service life; For explosion-proof applications, it is possible to customize ex intrinsically safe explosion-proof instruments, explosion-proof sensors, and use baking paint that is not easily reactive with other substances in the air to ensure the service life of explosion-proof weighing scales The company adopts the international standard U-shaped steel bridge structure concept, with 5-7 U-shaped main beams for each weighing platform (with stronger load-bearing capacity), steel plate thicknesses of 12mm, 14mm, 16mm, and multi fold design. According to different user usage scenarios, the load-bearing points can be selected to achieve humanized design.

4. Choose a scale with a foundation pit, and our company can provide a foundation map. After the foundation pit construction is completed, the scale can be shipped to the site for simultaneous installation.

5. Leave your contact information, phone number (company and personal phone numbers are guaranteed to facilitate detailed negotiations with you), email address (our company selects the appearance and parameters of sensors suitable for your use, as well as a quotation, so that you can purchase our products faster)

Customizing a weighing scale takes about 7-15 days, but if the area is too far or the foundation is not perfect, it may take about a month. We will try our best to produce the scale you need in the shortest possible time.